- Category

Quality assurance

The quality assurance system for our products includes all areas which contribute to the attainment of quality objectives. It is based on statutory requirements, customer requirements and the internal quality requirements of isel Germany AG / iselRobotik.

The quality assurance system ensures that the production processes are controllable and that only products that meet the respective specifications are forwarded to the next working stage. We hold DIN ISO 9001:2008 certification.

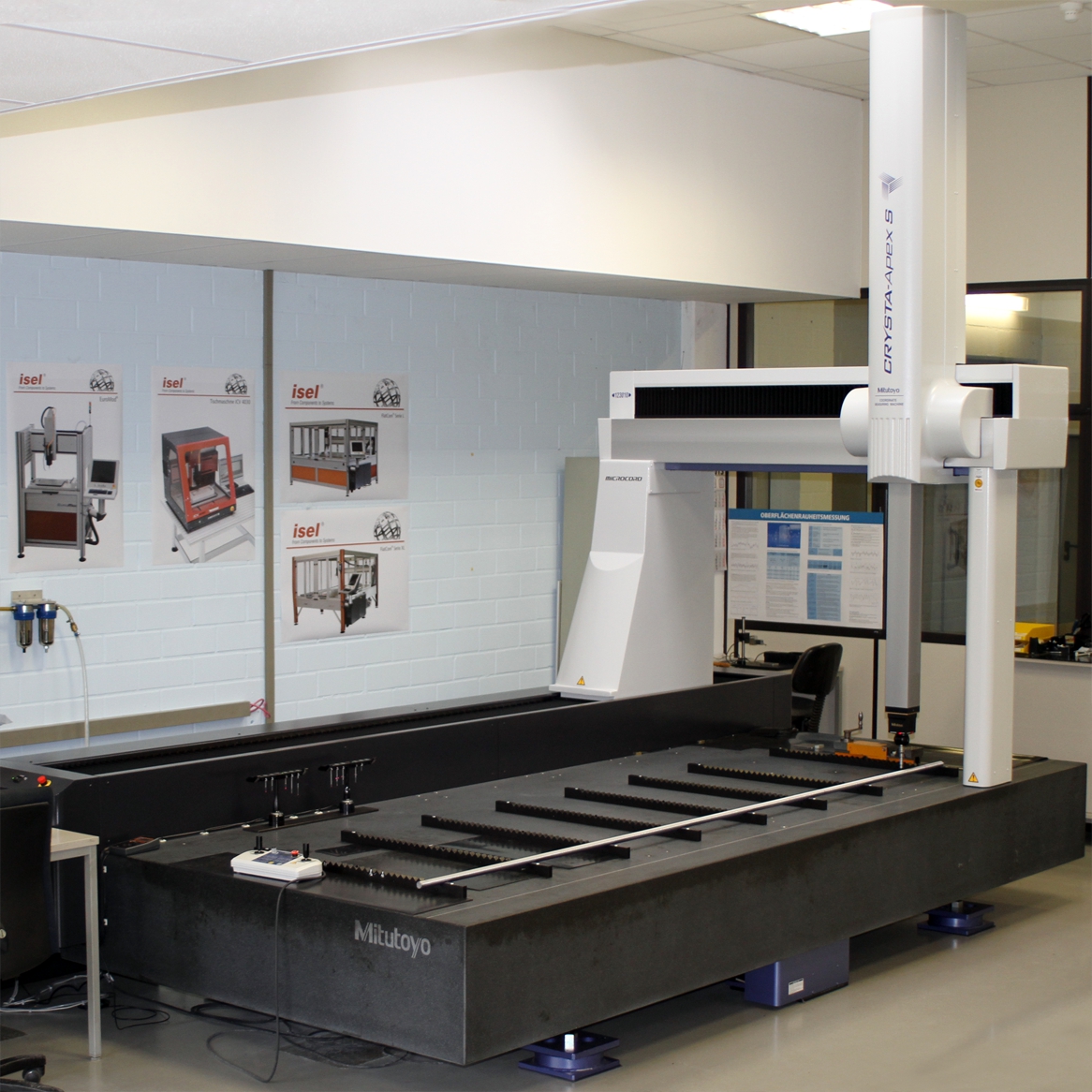

Coordinate measuring devices

Mitutoyo CRYSTA Apex S 123010 |

isel Germany | |

Technical DataX-Axes = 1205 mm Touch probeTP 200 Changing magazineSCR 200 Length measurement deviationMPE = (2,5+4,0L/1000)μm |

|

|

Mitutoyo Euro C 544 Apex |

||

Technical DataX-Axes = 500 mm Touch probeTP 200 Changing magazineSCR 200 Length measurement deviationMPE = (2,9+4,0L/1000)μm |

|

|

Mitutoyo Euro C 574 Apex |

||

Technical DataX-Axes = 500 mm Touch probeTP 200 Changing magazineSCR 200 Length measurement deviationMPE = (2,9+4,0L/1000)μm |

|

...and the quality requirements of our customers and isel Germany AG

Mitutoyosurface roughness testing deviceTyp: SJ - 201 P |

isel |

Wolpert hardness testing deviceTyp: DiaTestor 2 Rc |

isel |

Electrophysics layer thickness measuring deviceTyp: Minitest 600 B |

|

|

|

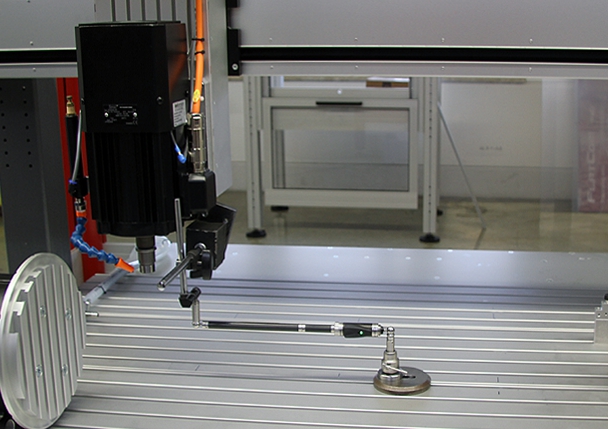

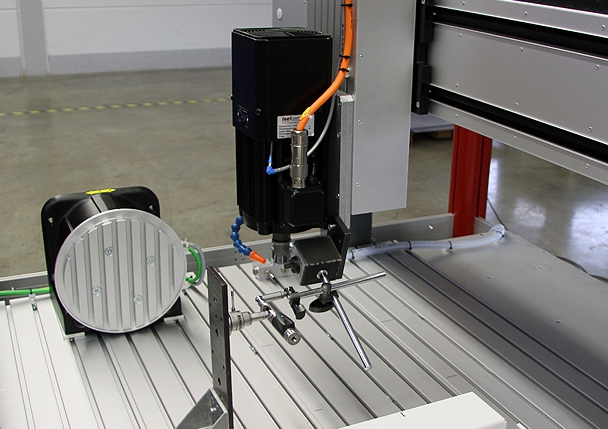

Machine accuracy (with QC 20)

| The QC 20 system permits the cable-less testing of our machines. Geometric and control machine errors such as perpendicularity, contouring errors, guide clearance, straightness errors and reverse clearance are detected by measuring the circularity. The system is traceable and is inspected by the manufacturer at regular intervals. | ||||

|

|

|

||

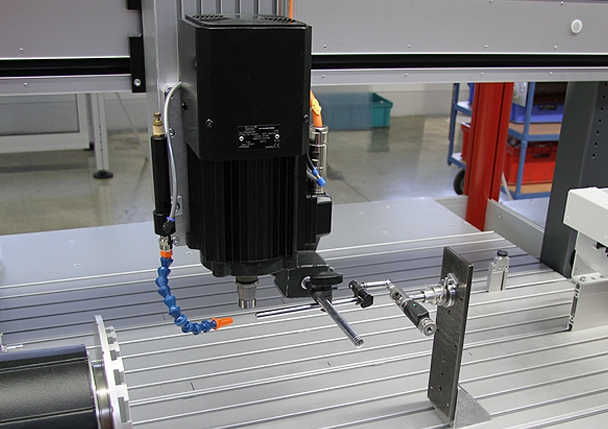

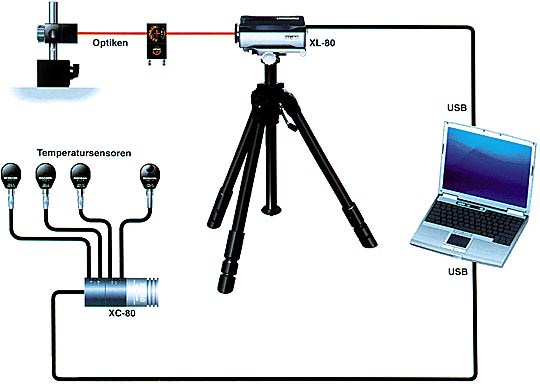

XL-80 laser interferometer

| The laser system for the calibration of machine tools and coordinate measuring devices is used by us for .... |

| ... position measurement | ... Tipping angle measurement | |

| The position measurement is the most commonly performed measurement on machines. The system records the positioning and repeat accuracy by comparing the position value displayed by the machine and the position actually recorded by the laser interferometer system. | is | In machine tools and coordinate measuring devices, the cause of positioning errors is frequently the tipping of axles. Due to the Abbe’s effect, the errors intensify with increasing distance from the axle guide. |

| ... Measurement of dynamic behaviour | ... Straightness measurement | |

| The dynamic measurement software allows movement sequences, speeds, accelerations, oscillations and the performance of servo drives to be ascertained. | The straightness measurement is used to ascertain the horizontal and vertical straightness of machine guides. Straightness errors have a direct impact on the positioning accuracy and linear accuracy of a machine. | |

|

|