Do you have any questions?

Your contact for CNC milling machines & CNC special machines

Jürgen Balzer

Phone: +49 (0) 6659 / 981-774

Fax: +49 (0) 6659 / 981-776

juergen.balzer@isel.com

Stefan Koch

Phone: +49 (0) 6672 / 86792-526

Fax: +49 (0) 6672 / 86792-777

stefan.koch@isel.com

Frank Schneider

Sales Manager

Phone: +49 (0) 6659 / 981-489

Fax: +49 (0) 6659 / 981-776

Mobile: 0151/524 279 70

frank.schneider@isel.com

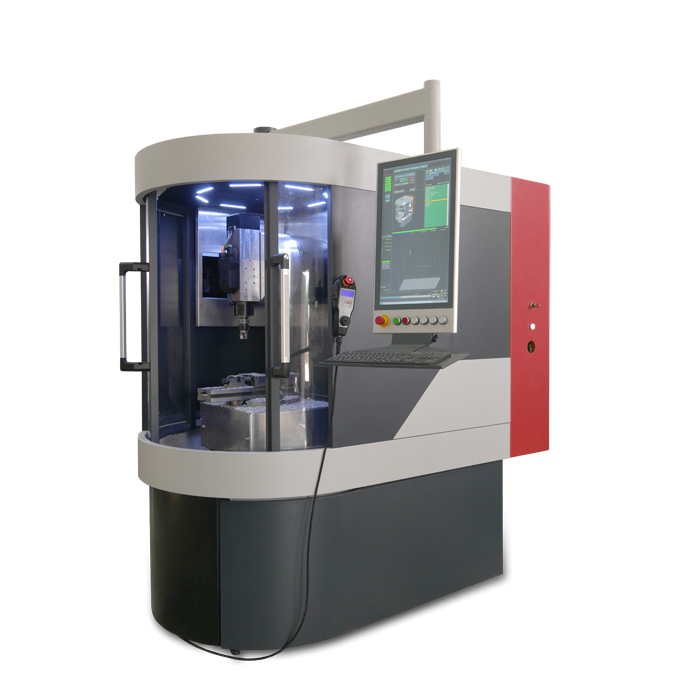

Universal CNC milling cell iMG 4040 / 6040 / 8040

With the iMG machine series, a 3/4/5-axis milling machine with solid mineral casting machine frame, metals as well as steel can be machined. The iMG milling machines not only boast an elegant design, but also have a compact but stable construction, allowing economical working in the smallest spaces. With covered linear guides and large ball screws, downtimes are minimised and the requirements for machining steel are met. Thanks to the external 15-fold tool changer, the working area is not restricted, with the result that even larger work-pieces can be machined with no restrictions.

Proven isel components including the isel spindle drives consisting of recirculating ball screws and preloaded linear bearings have been integrated into the successful combination of size and functionality. The iMG milling machines have been developed for high capacity, productivity and flexibility in order to gain a lot of machining space while at the same time taking up as little space as possible. An extensive range of accessories predestines the machine for numerous application areas from prototype construction to small series production. The solid mineral casting substructure offers a stable and solid platform.

Features:

- 3/4/5-axle operation can be extended

- 15-fold tool changer

- Working range not reduced during tool change

- Control panel with 21“ touch screen for easy operation

- Hand wheel for set-up operation

- Integrated lighting in the working area

- Recirculating ball screws in all linear axes all

guides covered - Rotating/swivel axes equipped with cast iron

block guides - Air-cooled milling spindle with SK30 tool holder

- Largely dimensioned recirculating ball bearing guides

in all linear axes - Chip collection tray incl. cleaning flap

- Integrated coolant pump

- Settling basin for coolant with cleaning opening

- Solid mineral cast machine bed

| IMG 4040 | IMG 6040 | IMG 8040 | |

| Traverse ranges X/Y/Z [mm]* | 400 / 400 / 400 | 600 / 400 / 400 | 800 / 400 / 400 |

| Table clamping surface WxD [mm] | 400 x 400 | 600 x 400 | 800 x 400 |

| Dimensions WxDxH [mm] | 1800 x 1300 x 1850 | 2000 x 1300 x 1850 | 2200 x 1300 x 1850 |

| Travel speed X/Y/Z | 20.000 mm/min | ||

| Repeatability | 0,02 mm | ||

| Drive motors | Servomotors | ||

| Drive elements X/Y/Z | Ball screws 25 x 10 / 25 x 10 / 25 x 10 mm, backlash-free adjustable | ||

| Milling spindle | 6,000 – 24,000 rpm with position sensing, sealing air and temperature-controlled cooling |

||

| Tool holder | SK30 | ||

| Control | PC-based (isel-CAN / Beckhoff) | ||

| Operation | 21“ touch screen, keyboard | ||

| Weight | approx. 2.500 kg | approx. 2.600 kg | approx. 2.800 kg |

| Connected loads | 400V / 16A | ||

| Item No. | 283001 0001 | 283002 0001 | 283003 0001 |