Motors

|

|

-

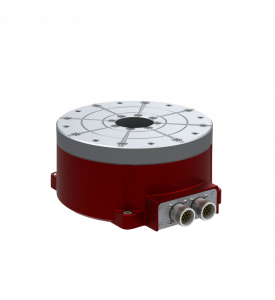

Torque motor iTM 180Learn MoreIn stock

Torque motor iTM 180Learn MoreIn stock -

Torque motor iTM 240Learn MoreIn stock

Torque motor iTM 240Learn MoreIn stock -

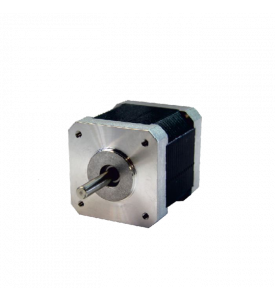

MS 048 HT-2 (NEMA 17)Learn MoreIn stock

MS 048 HT-2 (NEMA 17)Learn MoreIn stock -

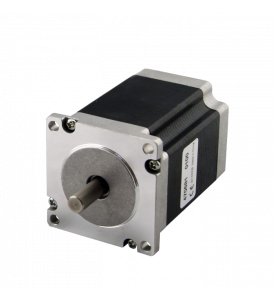

200 HT-2 (NEMA 23)Learn MoreIn stock

200 HT-2 (NEMA 23)Learn MoreIn stock

The isel motor range consists of drive motors with stepper, servo, linear and torque motors and the motors are all optimised for the positioning mode. Whether for simple solutions with stepper motors or highly dynamic movements with servo or linear motors, the robustly and field-tested electronics from isel offers a suitable solution for every requirement. isel motors feature high power density, high speed ranges, high overload capability and high levels of positioning and repeat accuracy.

Synchronous stepper motors are motors, in which the rotor is rotated by a controlled, gradually rotating electromagnetic field of the stator coils at a minimum angle. isel stepper motors are 2-phase stepper motors, which feature very smooth running and low resonance vibrations. Stepper motors are highly cost-effective solutions in the field of positioning controls.

Synchronous servo motors are the standard solutions for industrial use. The permanently energised brushless servo motor excellently meets the requirements for a servomotor. The low power density, efficiency, ease of controllability and the reduced purchase price, make the servo motor the ideal solution for industrial use. The permitted speed-torque characteristic curve is limited by the current and voltage limits by the controller. All isel servo motors are equipped with incremental motor encoders and holding brakes and different levels of protection are also available.

Synchronous linear motors offer completely new levels of productivity with increased dynamics and precision. In the linear motor, most of the mechanical transmission elements have been dropped. To multiply the power, several primary parts can be coupled to a secondary part. The linear motor is a low wear and tear and low maintenance drive unit, whose high level of accuracy is maintained over a long operating period. The components primary (coil) - and secondary part (magnetic strips) are delivered separately, with hardly any limits being set to the length of the linear unit. A motor system consists of primary and secondary sub-segments, a length measuring system and linear guide. Likewise direct route measurement for positioning without a linear measuring system is also possible.

Position-controlled feed drives are important components of any CNC solution. They considerable extent determines the productivity and the quality of motion. The motor as an energy carrier for movement and for holding the position required speed and torque, and speed and driving force for linear motors. Supporting assemblies such as holding brakes and motor encoder (encoder) are also available.

Through our modular system with various primary and secondary parts a large freedom of design is given. The core benefits are: the low wear, no backlash, no elasticity, high stiffness, low total mass and the large acceleration.

Matching controllers for our motors can be found here.