|

|

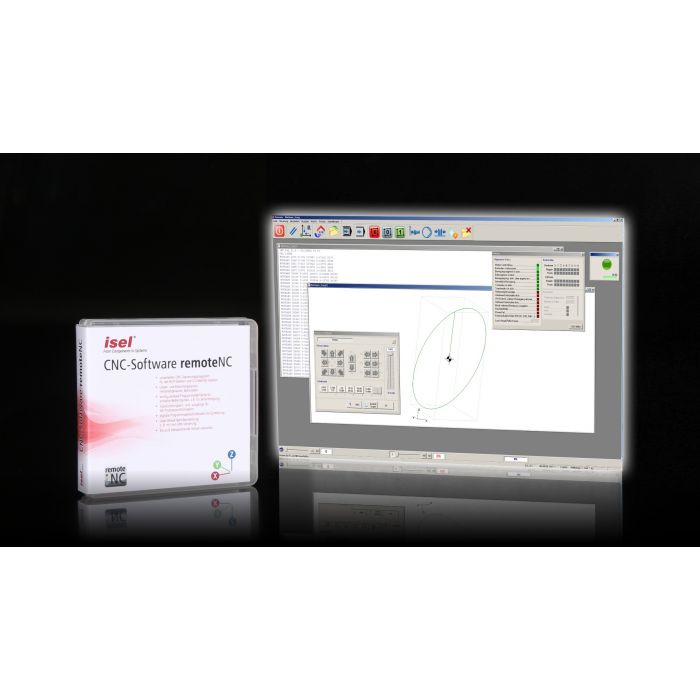

RemoteNC - Control software for Windows

General

- universal CNC control program for NCP files and G-code

- for additive and subtractive methods; Water jet and laser cutting

- linear and circular interpolation, Helix interpolation, drilling cycles

- configurable user interface for easy operation, series production, Handshake with master PLC

- Look ahead track editing with CAN control

- controllable up to 6 interpolating axes

RemoteNC is a universal control program for outputting files for machining methods milling, drilling, adhesive bonding, engraving, applying and water jet cutting or laser cutting / welding.

Supported file formats are the isel-specific NCP format (ASCII file with machining data generated by a CAM post-processor, the isel-specific CNC format (ASCII files in an expanded format for universal use in the process automation area, generated by ProNC) and the G-code format to DIN 66025.

RemoteNC is used first and foremost for controlling CNC machines operating different tasks and processes, which is why flexibility is a key feature of the program. A large choice of options allows easy adaptation to current requirements in each case.

- Support for digital joysticks

- "Fast file selection" control panel for serial production

- Milling / multiple output with movements

- Graphic depiction of the processing file with zero point anddimensions isel-NCP, DIN66025/G-code file formats

isel-NCP, DIN66025 / G-Code file formats

- Linear and circular interpolation, helical interpolation, drilling cycles

- Access to digital and analogue inputs and outputs

- When using a CAN controller: "On-the-fly" input/output(without stopping the movement) for metering applications

- Message window, messages in the status line, time delay,input of variable values

- Definition and use of machine positions(tool zero point, park position, home position, etc.)

Additional features for the isel-CNC file format (ProNC output format)

- Repeating loops, counting loops, unconditional and conditional branches

- Arithmetic and trigonometric functions

- Sub-program systems

- Real and symbol chain variables

- Loading and storing process variables

- Access to user-specific expansions, option to call up user software

Features

- runs with Windows operating systems (Windows 2000, XP, Vista, Win7 and Win8, Win10 (administrator rights required))

- compatible with previous software versions

- Processing of DIN66025 (G-code) file formats, NCP or CNC

- immediate processing without conversion, File translation or conversion

- integrated text editor with numerous features for rapid corrections to the present NC program

- Use of up to 6 interpolating axes (Cartesian coordinates system and 3 auxiliary axes)

- Look-ahead track processing with CAN controller

- Managing a milling spindle

- 2 I/O units can be used (max. 64 inputs, 64 outputs)

- Signalling inputs and outputs for process synchronisation

- manual axis movement with joystick, keyboard and mouse

- incremental processing and system monitoring for commissioning

- Configurable interface for user-friendly operation, serial production, handshake with master PLC, etc.

- Control panel for movement control, input/output, spindle and tool change with buttons

- Control panel for max. 6 handling axes independently of the interpolating axes

- available in various languages (German, English, French, Hungarian)